Майстерня

Кожен різальний інструмент — вимагає повторного заточення.

Головні відмінності хорошого ножа — продумана геометрія залізка, якість сталі, та грамотна термообробка.

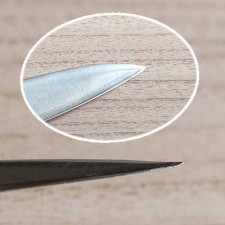

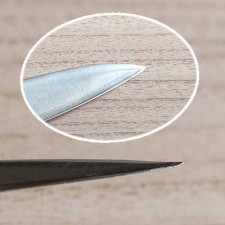

У базові поняття ножової геометрії входять: товщина тупія, форма спусків, і характер зведення, або іншими словами товщина різальної крайки.

Кожна складова може істотно впливати на якість різу і тривалість утримання гостроти.

Ножові майстри з Японії, роблять зведення на більшості виробів виключно тонким.

Це дає чудовий різ, але потребує дбайливого ставлення, з уникненням контакту р.к. з іншими предметами, що мають схожу твердість.

При нормальній експлуатації, заточний сервіс потрібен раз на кілька місяців, бо зовсім без заточки, може обходитися лише залізко яким не користуються.

Культура правильного поводження з добротним кухонним інструментом, в нашій країні тільки формується.

Вкоренилися забобони, і є випадки грубого та нецільового використання, але такі приклади поодинокі, і відбуваються в будь-яких сферах.

Наша компанія займається супроводом пропонованої продукції.

Ми відновлюємо гостроту, і усуваємо пошкодження.

Впевненість і спокій наших клієнтів, формуються не тільки на основі придбання оригінального товару, а й на наступній сервісній підтримці.

Заплановано поліпшення движка розділу Майстерня, тому ми не розміщуємо нових публікацій.

Роботи по відновленню ножів і заточуванню, ведуться в штатному режимі.

Деякі приклади "до і після" фотографуються, і будуть опубліковані у вже оновленому розділі.

На ремонті і заточці ніж Деба Tojiro Shirogami F-903 180mm. Кухня Японії включає безліч рибних страв. Сирої або відвареної, обсмаженої за рецептурою темпура і маринованої. Різноманітність рецептів велика, але їх об'єднує певний спосіб обробки. Японці, незважаючи на високу вартість продуктів, готують з риби філе, викидаючи деяку частину в відходи. Це відрізняється від прийнятого у нас стилю, нарізати її цілою на стейки. Deba призначений для отримання філе. Це асиметричне потужне залізко, яким можна зробити гарний і рівний зріз вздовж хребта. Потім за допомогою великого пінцета виймаються дріб...

Ремонт сильно загнутого кінчика, Gyuto Tojiro F-808, з подальшою заточкою. Компанія Fujitora Industries, робить чудові ножі, пропонуючи дійсно величезний асортимент. Головною відмінною рисою їх підходу до виробництва, є відточена технологія гарту. "Золотий перетин" фахівцями фірми точно знайдено, і зафіксовано. Взірцева повторюваність, у різних моделей з різних поставок, викликає повагу. Через наш сервіс, пройшли без перебільшення сотні виробів цього виробника, і всюди спостерігалась передбачувана і схожа поведінка сталі при заточуванні. Якби людина, яка взяла в руки цього "Шефа" що б погнут...

Ремонт кухарського ножа Takamura Migaki R2 Gyuto 210 mm. Компанія виробляє чудові ножові вироби, з якісної сталі. Є деякі прорахунки з балансом, проте загалом продукція чудова. Це залізко з серії, аналогічної з Tojiro High Speed Steel. Висока твердість гарту, і найтонше зведення, є особливими рисами цих висококласних ножів. Руків'я від Tojiro забезпечують кращий розподіл ваги, завдяки більшим розмірам і масі. Такий інструмент вимагає шанобливого ставлення, і вірної оцінки його призначення. В руках професіоналів, що мають досвід, залізка з порошкової сталі працюють без правки місяцями, викори...

EDC ніж Benchmade McHenry Williams 710 зі сталі M390. Прибув на ремонт з декількома ушкодженнями біля кінчика. Кромка від виробника була досить грубою, а підводи широкими. Відколи видалені повністю, а кромка відполірована до бритвеної гостроти. Заданий виробником кут, не має сенсу сильно зменшувати за одну заточку. Це призведе до зняття великої кількості металу, що зменшує ресурс залізка. З цієї причини кут було змінено всього на пів градуса на кожен бік. При подальшому заточуванні, його слід ще потроху збільшувати, бо в різучості на зразок кухонних ножів, у кишенькового складня немае потреб...

Зразкова заточка складного ножа Spyderco Paramilitary 2. З хорошим ножем з якісної сталі завжди приємно працювати. Результат в цьому випадку так само виходить чудовий. Досягти високої гостроти вдається порівняно швидко, а утримується вона довго. Іноді доводиться виправляти задані виробником, і далекі від ідеалу підводи до ріжучої кромки. У Spyderco це не рідкість. Робота з невеликим залізком має додаткову складність, бо найбільш відповідальних ділянок два, це кінчик і рікассо. Обидва елементи повинні бути виведені максимально рівно, незалежно від початкового стану. Навіть застосування спеціал...

Ремонт кінчика і заточка овочевого ножа Samura. Були сколи, і немає :) Працездатність повністю відновлена. Після вирівнювання кінчика і якісного полірування ріжучої кромки, ним знову можна довго працювати. Натисніть на світлини для збільшення зображень ...

Ремонт автоматичного ножа Protech GODFATHER лімітованої серії. Навіть рідкісний і дорогий екземпляр з обмеженим випуском, якому здавалося б місце виключно на полиці, цілком може бути edc інструментом. Кастом, яких випущено всього 40 шт, якраз такий приклад. Численні сліди від використання, додали брутальності. Технічний стан автоматики залишилося добрим. Було необхідно виправити геометрію ріжучої кромки. Відносно широкі підводи вже були, і щоб задати залізку кут атаки, при якому їм буде комфортно різати, їх довелося залишити. Компанія робить досить товсте зведення на нових виробах. Форма зал...

Ремонт Гьюто SAIUN Damascus 9006 від Seki Kanetsugu. Причина таких пошкоджень очевидна, - це був краш-тест. Навмисне нецільове використання по великих кістках. Завдяки чималій відстані від ріжучої кромки до початку дамаських візерунків, виправлення вдалося здійснити так, що не відразу віриться, що це один і той самий ніж, до і після. Сколи прибиралися вручну, максимально близько до межі можливого. Всі залізка від Kawamura-san, зведені тонко, і мають певний потенціал для відновлення без значного потовщення ріжучої кромки. Робота виконана філігранна. Ніж повернуто власнику. Натисніть на сві...

Ремонт сколів і заточка Сантоку Tojiro HSS F-517. Справжній професійний інструмент, високого гатунку. Це завжди повинен бути усвідомлений вибір, людини розуміє особливості використання. Хороший кухонний ніж, - це добре ріжучий в першу чергу. Наступна найважливіша особливість, це наскільки довго триватиме його гострота. Японські ножові вироби, відрізняються високою твердістю гарту, що дозволяє досягти рекордних показників по тривалості різу. Такие залізко не може застосовуватися безвідповідально. Досвід правильного поводження, отримується найчастіше через розуміння меж. На щастя наслідки багат...

Повторний ремонт овочевого ножа Tojiro Flash. Минув рік, і знову на відновлення потрапив маленький ніж для карвінгу і чищення овочів.Уже в повному наборі, з Шефом, Сантоку, двома Петті і ножем для м'яса.

Якщо взяти до уваги, що ножі експлуатуються постійно, протримався довго.

У домашніх умовах, термін між заточками може бути значно довшим.

Овочі продукт м'який, і затупити кромку при цільовому використанні вкрай складно.

Висока твердість сталі VG-10, дозволяє досягти дуже хороших інтервалів між заточками.

Дбайливе поводження, здатне відкласти необхідність в сервісі на роки.

Тут все залежить в...

Ремонт і заточка набору з шести ножів Tojiro Flash Damascus 63 шари. Комплект використовується професійним кухарем, і весь час в роботі.Стан для такої активної експлуатації можна оцінити як непоганий.

Усунення безлічі дрібних відколів, а також необхідне відновлення кінчиків, виконані оперативно.

М'ясний ніж довелося вирівнювати, оскільки погнуте залізко неможливо якісно заточити.

Процедура пройшла нормально, однак розумно уникати сильних бічних навантажень в майбутньому.

Завдяки обкладкам з м'якої сталі, що захищає ріжучий шар, лезо має деяку здатність гнутися.

Це і дозволило відновити почат...

Чотири потужних "туриста", з якими довелося серйозно попрацювати. Кваліфікована заточка всіх чотирьох, проводилася вперше з моменту придбання.Залізка активно використовувались, і робилися спроби їх заточування, наслідки яких необхідно було виправити.

Через широкі підведення, зроблені для забезпечення кращої стійкості ріжучої кромки, процес був тривалим.

За рівний час, можна заточити вдвічі більшу кількість японських кухонних ножів, завдяки тоншому зведенню.

Виправлення форми підводів, а вірніше їх формування наново, вкрай важливі, для якісного різу.

Таке залізко буде значно простіше підтримув...

Ремонт і відновлення кромки елітної кухарський пари Seki Kanetsugu. Перший сервіс за півтора року, з моменту придбання на 19-й виставці Сталева Грань в Києві.Відновлювати заточку на такому проміжку часу, необхідно будь-якому ножу, при активному використанні.

Не існує вічних речей, особливо в області тонких інструментів, якими щось розрізається, подрібнюється і т.д.

Це абсолютно нормально, і закономірно.

Якісні матеріали і точна підгонка всіх деталей, дозволили чудовим Santoku SAIUN 9003 і Paring knife SAIUN 9000 від Kanetsugu, пройти цю дистанцію гідно.

Мікарта руків'я і сталь на спусках, ма...

Відновлено черговий універсальний ніж Tojiro DP F-802. "Дамським догоджальникам", дістається найбільше, бо працюють вони в руках у господинь.Часто пошкодження дрібні, і нормально підлягають виправленню.

Головне, що поступово формується здорова культура поводження з хорошим кухонним ножем.

А не вічно тупою як лінійка смужкою м'якого металу, нездатною нормально різати.

Після кваліфікованої заточки, якісна японська сталь здатна утримувати високу побутову гостроту близько півроку.

Невпевнене проходженні паперового тесту, ймовірно вказує, що прийшов час відновлювати кромку.

Проміжок часу, в якому...

Черговий сюрприз від клієнтів. Великий і важкий промисловий ніж, придбаний для розрізання тортів.Він скоріше підійде для розрізання великих головок сиру, через свою товщину.

На жаль ріжучої кромки в звичному розумінні, на ньому не було, довелося нарізати.

Голитися в результаті їм буде незручно, але гострота була наведена. Для порівняння на фото, Шеф-ніж Fujiwara Kanefusa FKM Gyuto 210 мм клинок.Загальна довжина 335 мм.

Втрачається на його тлі. Натисніть на світлини для збільшення зображень ...

Чергова заточка декількох японських ножів Masahiro. Виробник відомий, також і за межами Японії.Завдяки хорошій якості та різноманітності пропонованих моделей.

Наш набір, з доступних за ціною, що абсолютно виправдовує витрачені кошти.

Головним аспектом, в продукції багатьох компаній з Країни Вранішнього Сонця, є асиметрична заточка.

Це данина традиції, з трохи сумнівною цінністю в наш час, і для західного користувача.

Робиться це для підвищення стійкості кромки і деякого поліпшення ріжучих властивостей, але додає труднощів з подальшим відновленням.

Фірма Seki Kanetsugu, дуже вміло обійшлася з ц...

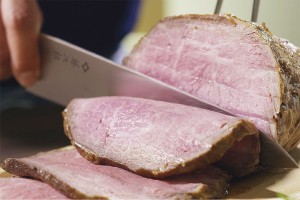

Пара цікавих м'ясних ножів, переданих для заточування постійним покупцем. Доставили для сервісу великий набір, в якому була пара примітних ножів.Перший Tojiro Senkou цікавий тим, що вже не випускають цю серію.Йому був потрібен ремонт кінчика, відламаного в результаті падіння на плитку.

Робота була виконана дуже гарно, зберігши естетику перської форми.

Це не тільки робоче залізко, а й витвір ножового мистецтва. Другий, утилітарний Chicken boning Tojiro DP F-803, отримав скол об порцелянову чашку, який був також повністю усунутий.

У традиційних японських Honesuki, асиметричні спуски та ріжуча ...

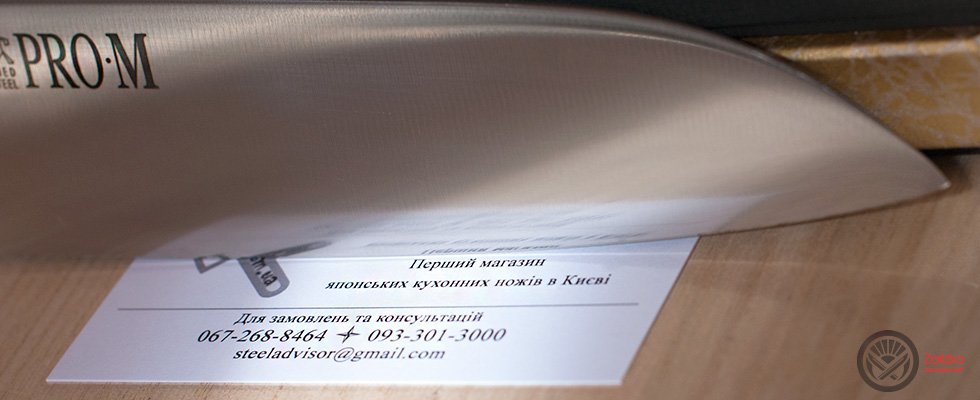

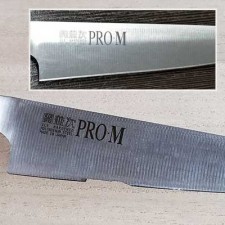

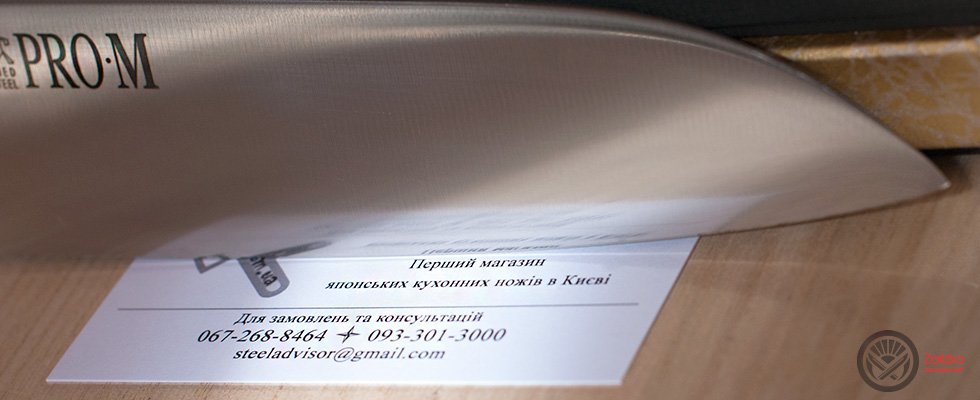

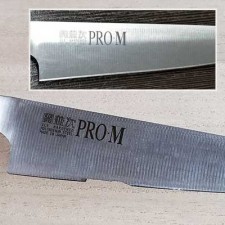

Відновлення універсального ножа Kanetsugu PRO-M 7001. Точилка-протягом, що знайома напевно всім, походить тільки для ножових виробів низької якості."Пластилінова" сталь на таких залізках дуже пластична, за рахунок цього практично немає ризику утворення відколів.

Інша питання, що і заточку такий метал не тримає, прирікаючи на постійне застосування подібних пристроїв.

Пристосування схожого зразка, просто здирають частинки м'якого металу, утворюючи мікро пилку, здатну деякий час триматися.

До якісного інструменту такий підхід неприйнятний, через різницю у властивостях ріжучої кромки.

Загартован...

Перший ремонт ножа Fujiwara Kanefusa з нержавіючої AUS 8. В особистій колекції було кілька зразків Fujiwara FKM, з яких залишився лише старший брат цього малюка.Решта були розпродані по виставках, бо користуватися всіма наявними в магазині ножами, немає ані необхідності, ані сенсу.

Якісне кухонне залізко, цілком може прослужити все життя. Його ресурс це дозволяє.

Замінюються вони швидше, через бажання спробувати щось нове.

Так і стають колекціонерами, в пошуках свого ідеального, найімовірніше неіснуючого ножа.Метал непогано показав себе під час заточки, і виправленні вістря.

При вирівнювання...

Чого не зробиш для друга. Планова заточка невеликого "підшефка" від Tojiro, привела з собою товариша.Чудо, виготовлене за часів союзу, і до цього дня ще зберігаюче функціональність.

З японським ножем не було несподіванок, а от спробувати повернути до тями дідуся, було цікаво.

Колись давно, він був значно довший, але оскільки професійний розмір в 30см на домашній кухні надлишковий, геометрію змінили.

Вийшла подоба сантоку за формою.

Підводи довелося нарізати заново, і зайняло це досить багато часу.

За опором точильним брускам, сталь, звичайна нержавійка, яку через широкі підводи, довго точити...